I. Introduction to FMEA in Automotive Industry

Failure Mode and Effects Analysis (FMEA) is an essential tool in the automotive industry, serving as a proactive approach to risk management. By systematically identifying potential failure modes, their causes, and effects, FMEA helps automotive engineers design safer and more reliable vehicles.

Failure Mode and Effects Analysis (FMEA) is a structured and systematic approach used to identify and mitigate potential failure modes in products, processes, or systems. In the automotive industry, where safety, reliability, and performance are paramount, FMEA plays a pivotal role in ensuring high standards of quality and compliance. This section expands on its importance, historical context, and how it is integrated into modern automotive engineering.

A. Why FMEA is Essential in the Automotive Sector

The automotive industry faces unique challenges due to the complexity of vehicle systems and the critical nature of safety components. FMEA offers several key benefits:

1. Risk Mitigation in Design and Manufacturing:

Automotive systems, such as braking, steering, and suspension, must function flawlessly under diverse operating conditions. FMEA helps identify potential failure points early in the design and manufacturing stages, reducing the risk of system malfunctions.

2. Regulatory Compliance:

Compliance with standards such as ISO 26262 for functional safety in road vehicles relies on robust risk assessment methodologies like FMEA.

3. Cost Savings:

By identifying and addressing potential failures before production, FMEA minimizes costly warranty claims, recalls, and reputational damage.

4. Enhanced Customer Satisfaction:

Vehicles with fewer defects and higher reliability contribute to improved customer trust and brand loyalty.

B. Integration of FMEA in Automotive Processes

The integration of FMEA into the automotive lifecycle includes:

1. Design Phase:

Design FMEA (DFMEA) evaluates potential failures in product design, such as material selection or system compatibility.

2. Manufacturing Phase:

Process FMEA (PFMEA) assesses potential failures in the production process, such as assembly errors or equipment malfunctions.

3. Service and Maintenance:

FMEA is also applied to predict and mitigate potential failures during the operational life of a vehicle, enhancing reliability.

C. Examples of FMEA Applications in Automotive Systems

FMEA is applied across various automotive systems to ensure robust performance and safety. Examples include:

Braking Systems: Identifying risks such as hydraulic fluid leakage or brake pad wear that could compromise stopping power.

Airbag Deployment Systems: Assessing sensor malfunctions or delayed deployment scenarios to enhance occupant safety.

Powertrain Systems: Mitigating risks of overheating, vibration, or material fatigue to ensure efficiency and longevity.

D. The Role of Cross-Functional Teams in FMEA

Effective implementation of FMEA in the automotive industry relies on collaboration among multidisciplinary teams, including design engineers, manufacturing experts, quality assurance professionals, and safety specialists. This ensures that potential failure modes are comprehensively analyzed from multiple perspectives.

E. Emerging Trends in FMEA for Automotive Engineering

The evolution of automotive technologies, such as electric vehicles (EVs), autonomous systems, and advanced driver assistance systems (ADAS), has expanded the scope of FMEA. Modern tools now incorporate Artificial Intelligence (AI) and machine learning to predict failure modes with greater accuracy and efficiency.

II. Importance of FMEA in Automotive Design and Manufacturing

- Ensuring compliance with regulatory standards.

- Enhancing customer satisfaction through reliable products.

- Reducing warranty claims and recall costs.

III. Key Concepts in FMEA

1. FMEA Methodology

The FMEA process involves systematically examining each component, subsystem, or process to identify potential failure modes, their effects, and causes.

- Design FMEA (DFMEA): Focuses on potential failures in product design.

- Process FMEA (PFMEA): Targets failures in manufacturing or assembly processes.

IV. Steps in Conducting FMEA

1. Identifying Failure Modes

Failure modes represent ways in which a component or system can fail. For instance, in a braking system, a failure mode could be "insufficient braking force."

2. Assessing Effects and Causes

The effects describe the consequences of a failure. For example, insufficient braking force may lead to increased stopping distances, affecting vehicle safety. Causes might include material defects or incorrect assembly.

3. Calculating Risk Priority Number (RPN)

The RPN is calculated using the formula:

RPN = S × O × D

Where:

𝑆 = Severity of the failure.

𝑂 = Likelihood of Occurrence.

𝐷 = Likelihood of Detection.

V. Case Study Overview: Application of FMEA in Automotive Braking System

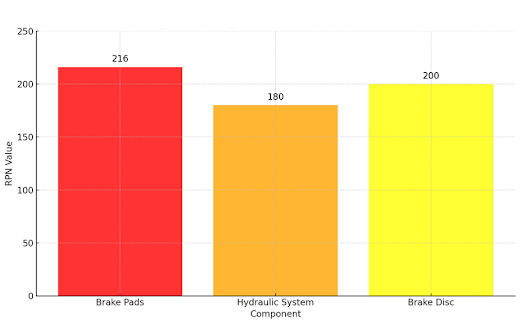

- Components like brake pads and hydraulic systems had the highest RPNs, indicating critical areas for risk mitigation.

- Mitigation actions such as improving materials and introducing advanced technologies were proposed to address high-risk failure modes.

- Proactive design improvements significantly reduced potential risks and enhanced the reliability of the braking system.

VI. FMEA Implementation Process

1. Team Formation and Training

An interdisciplinary team of design engineers, process engineers, and quality assurance experts was formed. Training sessions were conducted to ensure a uniform understanding of FMEA methodology.

2. Failure Mode Identification in Braking Systems

Potential failure modes identified included:

- Brake pad wear.

- Hydraulic fluid leakage.

- Sensor malfunction.

3. Assigning Severity, Occurrence, and Detection Rating

The team assigned ratings for each failure mode:

- Severity (S): Assessed the impact of failure on vehicle safety.

- Occurrence (O): Evaluated the likelihood of failure.

- Detection (D): Determined the probability of detecting the failure before it occurs.

VII. Analysis of FMEA Results

1. Identification of High-Risk Components

High-risk components were determined based on their RPN values, which highlight the combination of severity, occurrence, and detection ratings. Components with the highest RPN values were prioritized for detailed analysis and immediate corrective actions.

- Brake Pads: High RPN=216, primarily due to excessive wear and significant safety implications.

- Hydraulic System: RPN=180, driven by the potential for fluid leakage, which can severely impair braking performance.

- Brake Disc: RPN=200, due to risks associated with overheating, leading to reduced braking efficiency.

- Brake Pads exhibit the highest RPN (216), primarily due to excessive wear and its significant impact on braking performance.

- Hydraulic System has an RPN of 180, indicating risks associated with fluid leakage.

- Brake Disc ranks high as well with an RPN of 200, reflecting concerns related to overheating.

2. Detailed Analysis of Failure Modes

A. Brake Pads: Excessive Wear

- Cause: Suboptimal material quality or prolonged usage without maintenance.

- Effect: Reduced braking force, leading to longer stopping distances.

- Analysis Insight: Given the severity of this failure mode, enhanced materials with higher durability and wear resistance are recommended.

B. Hydraulic System: Fluid Leakage

- Cause: Degradation of seals over time or improper assembly.

- Effect: Sudden or gradual loss of braking power, posing a critical safety hazard.

- Analysis Insight: Introducing advanced sealing technologies and regular system checks can significantly mitigate this risk.

C. Brake Disc: Overheating

- Cause: Frequent use of brakes under heavy loads or prolonged braking periods.

- Effect: Warping of the disc and reduced friction efficiency.

- Analysis Insight: Employing heat-resistant materials and improving cooling mechanisms can address this issue effectively.

The RPN (Risk Priority Number) serves as a quantifiable metric to prioritize risks:

RPN = S × O × D

Where:

S: Severity of the effect on vehicle safety and performance.

O: Likelihood of the failure occurring.

D: Probability of detecting the failure before it impacts operations.

|

Component |

RPN Before Mitigation |

RPN After Mitigation |

|

Brake Pads |

216 |

108 |

|

Hydraulic

System |

180 |

90 |

|

Brake Disc |

200 |

80 |

4. Mitigation Strategies for High-Risk Areas

Based on the analysis, several actions were recommended and implemented:

1. Enhanced Materials:

Development of high-durability materials for brake pads and discs to withstand wear and high temperatures.

2. Improved Detection Mechanisms:

Introduction of sensors to detect early signs of fluid leakage and overheating.

3. Regular Maintenance Protocols:

Establishment of maintenance schedules to replace worn components before they fail.

4. Design Improvements:

Optimizing component geometry and materials for better performance under stress.

5. Overall Impact of FMEA Analysis

The FMEA analysis provided actionable insights, which directly contributed to improved safety, reliability, and performance of the braking system. Key impacts included:

- Risk Reduction: High-risk failure modes were mitigated effectively, as evidenced by reduced RPN values.

- Enhanced Safety: Proactive identification of critical risks ensured safer vehicle operations.

- Cost Efficiency: Early detection and mitigation minimized costly warranty claims and recalls.

VIII. Challenges in FMEA Implementation

1. Common Pitfalls

- Lack of cross-functional collaboration.

- Inadequate training on FMEA principles.

2. Strategies for Overcoming Challenges

- Regular workshops and knowledge-sharing sessions.

- Utilizing software tools to streamline the FMEA process.

IX. Benefits of FMEA in Automotive Industry

FMEA offers numerous advantages:- Improved product reliability.

- Enhanced safety compliance.

- Cost savings through early detection of design flaws.

X. Conclusion and Future Directions

XI. Literature

Author: OHS Consultant

Post a Comment for "Case Study: FMEA in the Automotive Industry"