2. Types of FMEA

A. Design FMEA (DFMEA)

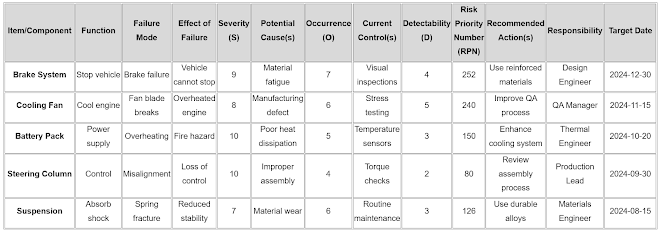

Design Failure Mode and Effects Analysis (DFMEA) systematically identifies potential failure modes in a product's design and evaluates their effects, causes, and corresponding mitigation strategies. Below is a comprehensive tabular representation of DFMEA:

Key Notes

- Severity (S), Occurrence (O), Detectability (D): Each parameter is rated on a scale of 1 to 10, where 1 represents minimal impact or likelihood and 10 indicates critical risk.

- Risk Priority Number (RPN): Calculated as 𝑅𝑃𝑁 = 𝑆 × 𝑂 × 𝐷. Higher RPN values indicate priorities for action.

- Recommended Actions: Proposals for addressing high RPN values.

- Responsibility and Target Date: Assign ownership and deadlines for implementing corrective measures.

This structured DFMEA table allows for a focused, systematic approach to design risk management, ensuring product reliability and safety.

B. Process FMEA (PFMEA)

Process Failure Mode and Effects Analysis (PFMEA) is a structured approach to identify and evaluate potential failure modes in manufacturing or operational processes. It focuses on process-specific risks and provides a framework to mitigate them effectively. Below is a detailed tabular representation of PFMEA:

Key Notes

- Severity (S), Occurrence (O), Detectability (D): Rated on a scale of 1 to 10, with higher numbers indicating greater severity, likelihood, or difficulty in detecting the issue.

- Risk Priority Number (RPN): 𝑅𝑃𝑁 = 𝑆 × 𝑂 × 𝐷. High RPN values require immediate action.

- Recommended Actions: Suggestions to mitigate high-risk failure modes.

- Responsibility and Target Date: Assign accountability and set clear deadlines for corrective measures.

This PFMEA table ensures a systematic evaluation of process risks, prioritizing safety, quality, and efficiency in manufacturing operations.

3. Key Components of FMEA

Failure Modes and Effects Analysis (FMEA) is a structured approach to identifying and analyzing potential failure modes in a system, process, or product. It helps prioritize actions based on the risk associated with those failure modes. Here are the key components of FMEA, presented in a flowchart and table.

|

Component |

Description |

|

Process/Product to Analyze |

Define the system, product, or process to be analyzed for potential

failures. |

|

Failure Mode |

List possible ways the process or product could fail (e.g.,

mechanical failure, design flaw). |

|

Effect of Failure |

Describe the impact of each failure mode on the system, process, or

product. |

|

Severity Rating (S) |

Assign a severity rating (usually 1–10) to each effect based on its

impact on the system. |

|

Cause of Failure |

Identify the potential causes of each failure mode (e.g., human

error, material defect). |

|

Occurrence Rating (O) |

Assign an occurrence rating (1–10) indicating the likelihood of the

failure occurring |

|

Detection Controls |

Identify current controls in place that can detect the failure mode

before it affects the system. |

|

Detection Rating (D) |

Assign a detection rating (1–10) indicating the likelihood of

detecting the failure before impact. |

|

Risk Priority Number (RPN) |

Calculate the RPN as RPN=S×O×D, which helps prioritize failure

modes by risk. |

|

Action Plan |

Develop an action plan to address high-RPN failure modes, focusing on

reducing severity, occurrence, or improving detection. |

|

Implementation and Monitoring |

Implement the action plan and monitor its effectiveness in reducing

the risks of failure. |

4. Applications of FMEA in Various Industries

- Identifying hazardous reactions in chemical processes.

- Preventing equipment failure in reactors, pipelines, and storage tanks.

- Assessing risks in wastewater treatment facilities.

- Improving the reliability of air filtration systems.

- Enhancing the safety of critical components like braking systems.

- Reducing defects in assembly lines.

5. Advanced Techniques in FMEA

- Real-Time Data Integration: DFMEA relies on continuous input from sensors, monitoring systems, and operational feedback to dynamically update failure assessments.

- Adaptive Risk Assessment: As conditions change, such as environmental factors, material degradation, or usage patterns, DFMEA adapts its risk evaluations.

- Proactive Decision-Making: With real-time insights, DFMEA supports immediate corrective actions, reducing downtime and improving reliability.

- Enhanced Predictive Maintenance: By integrating with predictive maintenance tools, DFMEA identifies potential failures before they occur, minimizing disruptions.

|

Step No. |

Step |

Description |

Tools/Techniques Used |

Outcome |

|

1 |

Establish a Baseline FMEA |

Conduct a traditional FMEA to identify failure modes,

effects, causes, and mitigation strategies. |

FMEA Templates, Brainstorming |

A foundational risk assessment for reference. |

|

2 |

Integrate Real-Time Monitoring Systems |

Deploy IoT sensors and monitoring tools to capture live

operational data. |

IoT Devices, SCADA Systems |

Continuous data stream for dynamic analysis. |

|

3 |

Develop a Data Analysis Framework |

Build algorithms or use software to process real-time data

and identify patterns of failure. |

Machine Learning Models, Statistical Tools |

Real-time insights into evolving risks. |

|

4 |

Link Dynamic Data to FMEA Parameters |

Map live data to Severity, Occurrence, and Detectability

metrics to update Risk Priority Numbers (RPN). |

Data Analytics Platforms, ERP Integration |

Adaptive updates to risk evaluations. |

|

5 |

Refine Mitigation Strategies Continuously |

Use updated RPN values to propose and implement new risk

reduction strategies. |

Root Cause Analysis, Process Optimization |

Improved and targeted mitigation plans. |

|

6 |

Implement Feedback Loops |

Establish mechanisms to evaluate the effectiveness of

actions and refine the DFMEA process further. |

Performance Dashboards, Feedback Mechanisms |

Continuous improvement in risk management. |

- Clarity: Each step is clearly defined, with associated tools and expected outcomes.

- Actionability: Offers a roadmap for teams to implement DFMEA systematically.

- Adaptability: Enables integration with various tools and technologies tailored to specific industries.

AI-Driven FMEA represents the next evolution of traditional Failure Mode and Effects Analysis by leveraging artificial intelligence and machine learning technologies. This approach enhances the identification, analysis, and mitigation of failure modes with greater accuracy, speed, and scalability, making it a valuable tool for industries with complex systems and processes.

A. Key Features of AI-Driven FMEA

1. Automated Failure Identification

AI algorithms analyze historical data, sensor readings, and operational patterns to identify potential failure modes without manual input.

2. Advanced Predictive Analytics

Machine learning models predict the likelihood of failures based on real-time data, operational conditions, and historical trends.

3. Enhanced Decision Support

AI provides recommendations for mitigating risks by simulating the impact of different actions, enabling data-driven decision-making.

4. Continuous Learning and Adaptation

With machine learning, the system evolves by learning from new data, refining its predictions and risk assessments over time.

5. Scalability Across Complex Systems

AI handles large datasets and complex interdependencies, making it suitable for industries like aerospace, automotive, and manufacturing.

B. Steps to Implement AI-Driven FMEA

The following table outlines the steps to implement AI-Driven Failure Mode and Effects Analysis (AI-Driven FMEA), providing a structured and comprehensive guide.

|

Step No. |

Step |

Description |

Tools/Technologies |

Expected Outcome |

|

1 |

Data Collection and Preparation |

Collect and preprocess historical and real-time data,

including failure logs and sensor data. |

IoT Sensors, Data Warehouses, ETL Tools |

Clean and well-organized dataset for AI analysis. |

|

2 |

Model Development and Training |

Develop AI/machine learning models to analyze failure

patterns and predict risks. |

Machine Learning Frameworks (TensorFlow, PyTorch) |

Predictive models for failure risk assessment. |

|

3 |

Integration with FMEA Framework |

Map AI insights to FMEA parameters (Severity, Occurrence,

Detectability) and automate RPN calculations. |

ERP Systems, AI Integration APIs |

Automated and real-time updates to FMEA analysis. |

|

4 |

Real-Time Monitoring and Updates |

Continuously track system performance and update failure

predictions dynamically. |

SCADA Systems, Real-Time Dashboards |

Live insights into risk and system health. |

|

5 |

Feedback and Refinement |

Use outcomes and operational feedback to refine AI models

for better accuracy. |

Feedback Loops, Model Retraining Tools |

Improved accuracy and adaptability of predictions. |

|

6 |

Actionable Insights and Recommendations |

Provide prioritized, data-driven recommendations for

mitigating risks and improving processes. |

Decision Support Systems, Predictive Analytics |

Clear, actionable plans for risk mitigation. |

C. Applications of AI-Driven FMEA

1. Automotive Industry

Real-time analysis of connected vehicle systems to predict component failures.

Adaptive risk management for electric and autonomous vehicles.

2. Healthcare

Monitoring medical equipment and patient data to prevent device malfunctions or medical errors.

3. Aerospace

Predictive failure analysis for aircraft components under varying environmental conditions.

4. Manufacturing

Identifying defects in assembly lines and optimizing process controls.

5. Energy Sector

Predicting failures in renewable energy systems like wind turbines and solar panels.

D. Benefits of AI-Driven FMEA

- Accuracy and Precision: AI eliminates human bias and errors, providing accurate risk assessments.

- Proactive Risk Mitigation: Predictive capabilities enable early detection and prevention of potential failures.

- Cost Savings: Reduces downtime and maintenance costs by preventing failures before they occur.

- Scalability: Easily adapts to complex and large-scale systems.

- Speed: Processes vast amounts of data quickly, accelerating decision-making.

- Data Quality and Availability: AI depends on high-quality, comprehensive data for accuracy.

- Integration Complexity: Incorporating AI into existing FMEA frameworks requires significant technical expertise.

- Initial Costs: Development and deployment of AI-driven systems can be expensive.

- Ethical Concerns: Automated decision-making raises questions about accountability and trust.

- Solution: AI algorithms were developed to analyze data from vehicle sensors in real-time, identifying patterns leading to sensor degradation.

- Outcome: Sensor reliability improved by 30%, and downtime was reduced by 20%, ensuring safer autonomous vehicle operations.

6. Challenges and Solutions in FMEA Implementation

- Subjectivity in Ratings: Variability in severity, occurrence, and detectability scores.

- Resource Intensiveness: Requires significant time and expertise.

- Complex Systems: Difficult to analyze multifaceted processes.

- Use standardized templates to minimize subjectivity.

- Invest in training for FMEA teams.

- Employ software tools for complex systems.

7. Case Study: FMEA in Chemical Manufacturing

- Conducted a PFMEA to identify failure modes like fouling and corrosion.

- Assigned high severity and occurrence ratings to these modes.

- Implemented preventive actions, including enhanced cleaning protocols and material upgrades.

8. Conclusion

9. References

- Stamatis, D. H. (2003). Failure Mode and Effect Analysis: FMEA from Theory to Execution. Quality Press

- EC 60812:2018 - Failure Modes and Effects Analysis (FMEA) and Failure Modes, Effects, and Criticality Analysis (FMECA).

- AIAG & VDA FMEA Handbook (2019)"A collaborative manual developed for automotive applications, offering a structured approach to implementing FMEA"

- Crow, K. (2002). Failure Modes and Effects Analysis (FMEA): Applied to Risk Management. DRM Associates.

- Ford Motor Company. (2001). Ford FMEA Handbook "An industry-specific guideline for applying FMEA in automotive manufacturing"

- Dyadem Press (2003). Guidelines for Failure Mode and Effects Analysis (FMEA) for Process Industries.

- NASA (2008). System Safety Handbook, Chapter 8: Failure Modes and Effects Analysis.

- Industry-Specific Standards: AS9100 for aerospace applications and ISO/TS 16949 for automotive supply chains.

- Software Documentation "User guides for tools like PTC Windchill Quality Solutions, Reliability Workbench, or Siemens Teamcenter FMEA"

Author: OHS Consultant

Post a Comment for "Failure Mode and Effects Analysis (FMEA) for Industrial Applications"